Pellet heating

The most comfortable way to heat with wood

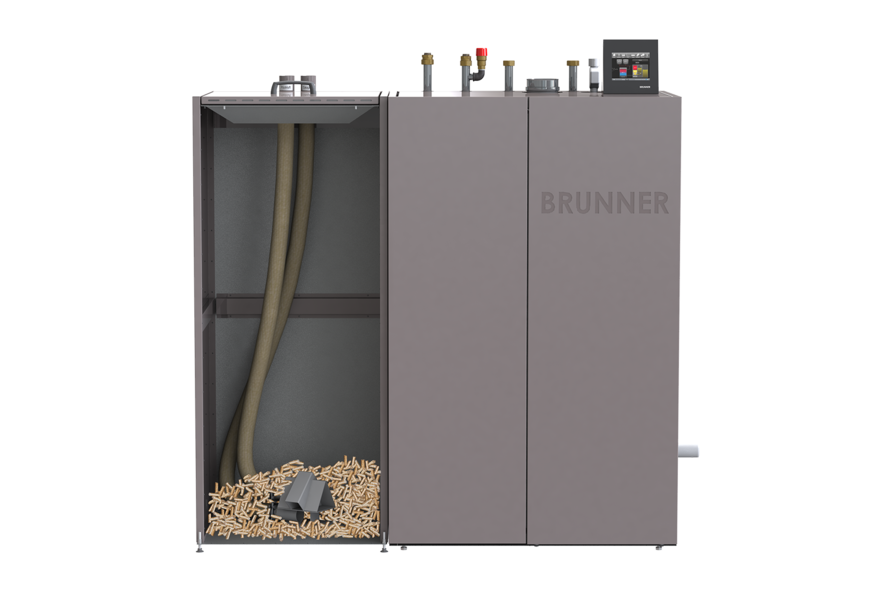

Fully automatic from the pellet store to the heater

Every product can only become as good as its builder's aspirations dictate. We always work with the aim of building the best boilers and heating solutions for wood fuel. Heating the Bavarian way.

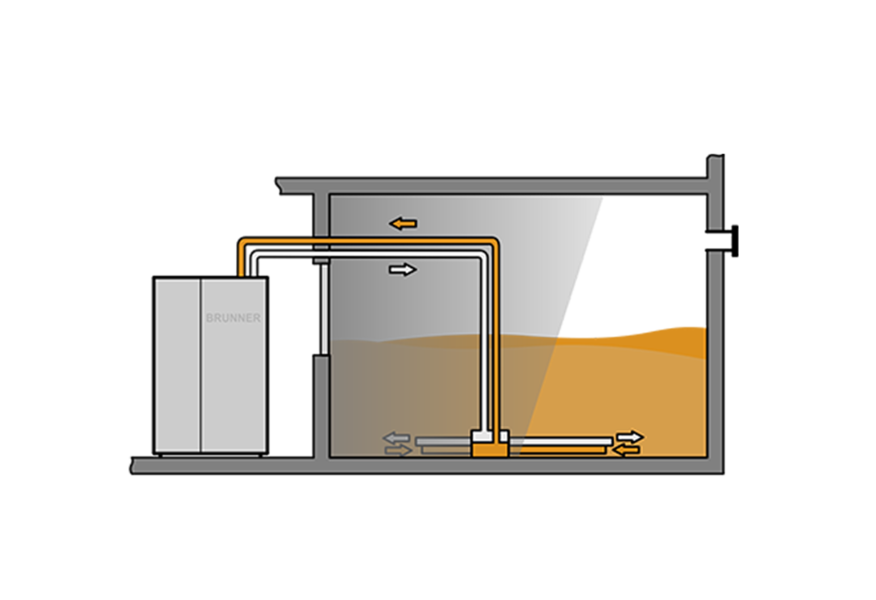

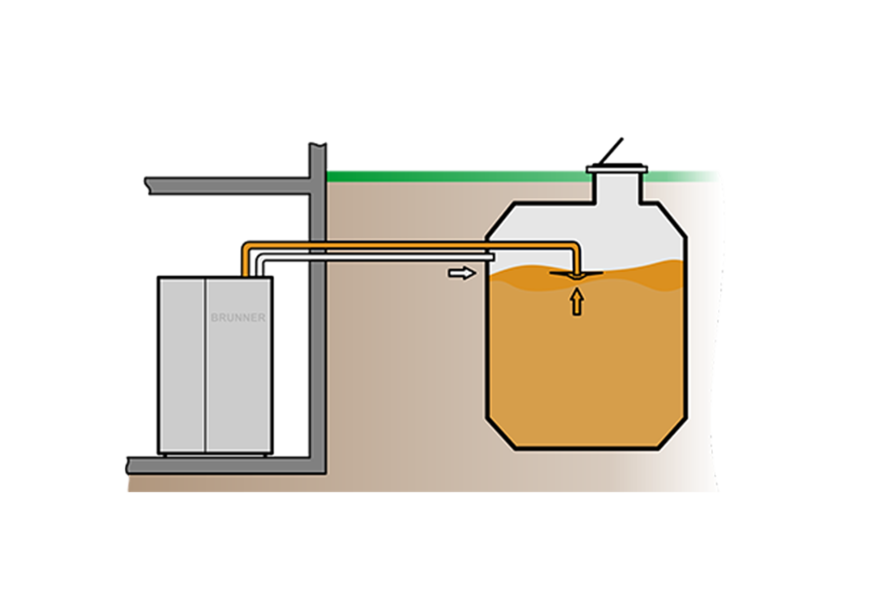

As comfortable as oil heating, but with renewable and regionally available fuel. The wood pellets are delivered in a truck and blown into the store room of the building. The annual tank and the boiler are connected via a hose system. The pellets are automatically "sucked in" by the boiler. Ignition, control, boiler cleaning and ash removal are also fully automatic in a pellet heating system.

- Turnkey and reliable comfort solutions

- Ideal for detached houses and apartment buildings

- Suitable for new and old buildings

- Combination with photovoltaics or solar thermal energy possible

- Eligible for subsidies

- Made in Germany

Tip

Biomass is popular

Take your chance and get the current subsidy for existing buildings: Old heating systems in existing buildings are replaced with new, lower-emission devices that generate heat with renewable energy. To receive the subsidy, it is important to apply for it in advance directly on the BAFA page.

One of the smallest pellet condensing boilers in the world

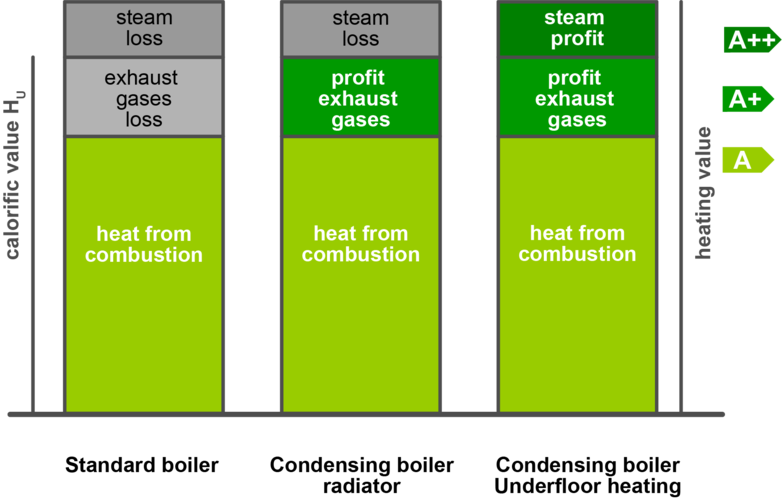

Heating even more efficiently with condensing technology: This technology extracts the remaining heat from the flue gases. The water vapour contained in the exhaust gases is condensed. The heat thus released is additionally fed into the heating system. The efficiency is up to 15 % higher than that of a conventional pellet boiler.

With a footprint of only 0.53 m² (0.84 m² incl. hot water tank), space problems disappear completely. The boiler output automatically adjusts to the heat demand in a wide range from 4 kW to 17 kW. With the tested supply air set, room-air-independent operation is permitted in new buildings but also in existing buildings that have been renovated for energy efficiency. With a flue gas pipe from the boiler to the chimney, the BPH is also available as a calorific value version with a higher flue gas temperature and can usually be operated without problems on existing chimneys up to a diameter of 150 mm (5.9 inches). If a chimney renovation is necessary, BRUNNER supplies a coordinated chimney renovation package in DN 100 mm. Fuel supply is simple: with a weekly container with a footprint of only 0.36 m², a bag silo or larger pellet store.

Pellets instead of oil

The change from an old oil heating system to pellets is simple. The BRUNNER pellet boiler is installed instead of the old boiler. Dimensions, connections and control are designed in such a way that the connection to the existing central heating system can be made without great effort. The pellet store is set up in the old tank room. With fabric tanks, this can be done quickly and without structural measures.

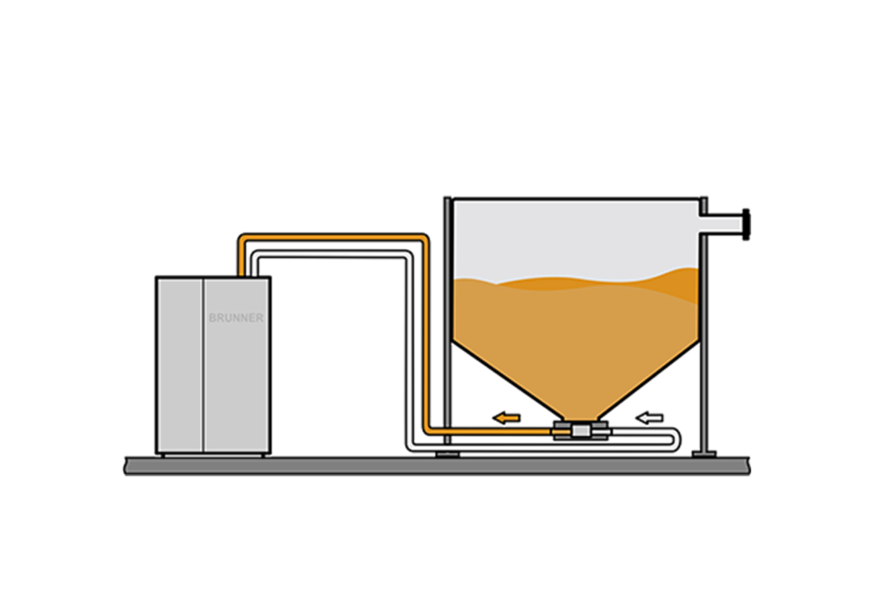

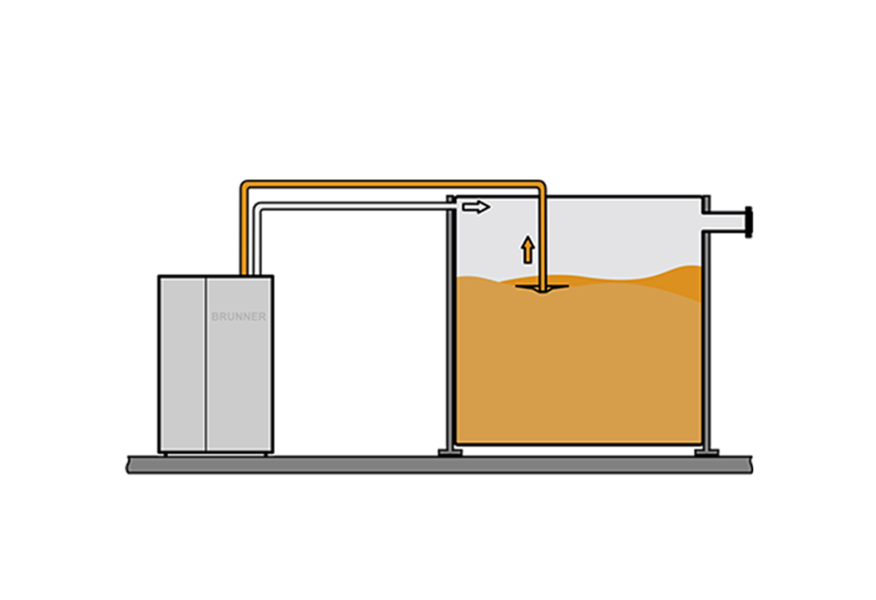

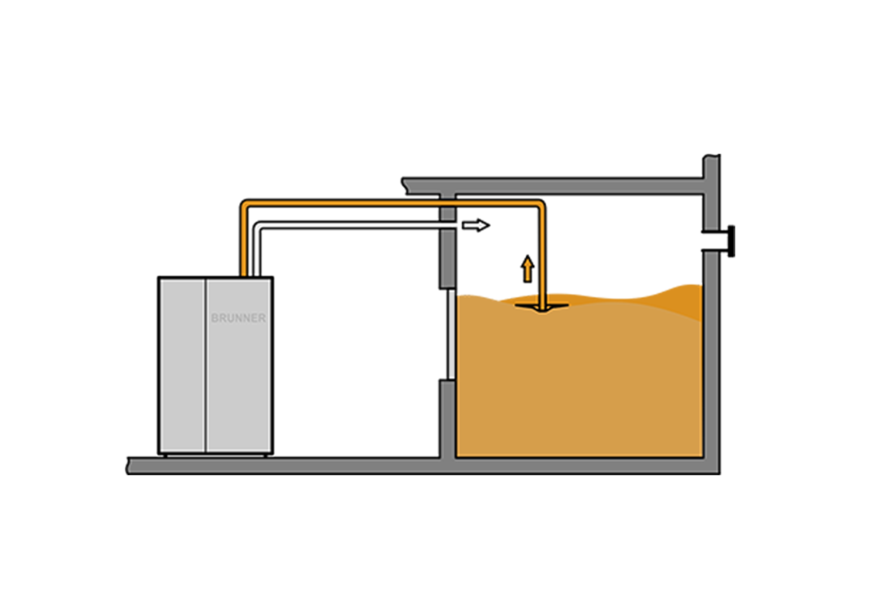

The pellets arrive at the boiler fully automatically. In kit system solutions, pneumatic suction systems have proven reliable. The pellets are extracted from above with a movable suction head or from below by means of permanently installed suction probes. The pellet boiler is equipped with appropriate hose connections and has an integrated suction turbine.

Emissions and efficiency

With its smallest CO² footprint, pellet combustion heating is probably the most efficient way to heat. When using surface heating systems such as underfloor heating, the flue gas temperatures are in the range of 28-38 °C. (82.4 - 104 degrees Fahrenheit) The emission values are far below the strict legal threshold values without additional separation and filtering equipment. This once again demonstrates the well-known excellent combustion quality of all BRUNNER products. Boiler pump, expansion vessel, boiler safety group, controls for boiler, heating circuits, hot water and solar are all integrated.

In conjunction with the BRUNNER heating centre the BPH can be extended and combined as required: Hot water preparation via fresh water station, additional heating circuits, use of surplus solar power (PV integration). And all this with a single control and a uniform user interface: With just one glance at the glass touch display, you can see all the important parameters regarding the status of the boiler as well as buffer tank temperatures. A simple and

clear display ensures self-explanatory operation of the

entire heating system.

Practical tips

The BPH is the only pellet boiler on the market with infinitely variable fuel metering and combustion control via lambda probe and differential pressure transmitter (air flow measurement). This completely compensates for all fuel quality, supply air and flue gas routing and ambient conditions. The excellent calorific value utilisation is also possible with buffer operation and a spread of up to 50 K between the flow and return temperatures. A return flow boost is not required. Due to the low boiler water content and an optimised ignition strategy, it reacts very quickly to heat demand. The charge pump and expansion vessel are integrated in the boiler. Operation directly on heating circuits and hot water tanks are also possible without a buffer tank. A 200 litre hot water storage tank is also available.

Operation and maintenance

The BPH runs remarkably quietly and is designed for low-maintenance operation. Automatic cleaning and sliding combustion grate ensure low operating effort. Emptying the ash box is necessary approx. 3-4 times per year, depending on fuel requirements - this is displayed on the control panel.

Condensing boiler technology

Condensing technology from BRUNNER can be combined with radiators, underfloor or wall heating. Especially with low-temperature heating systems, the return temperature is low enough to trigger condensation of the water vapour in the flue gas.

With conventional combustion, the unused flue gases with their water vapour content escape through the chimney at a relatively high temperature. This "residual heat" can only be used for heating with condensing technology. By further cooling the heating gases in the boiler, the flue gas losses are minimised and the water vapour contained condenses in the heat exchanger. The additional heat gained from the condensation and the lower flue gas temperature is fed into the heating system. Heating systems with condensing technology make almost complete use of the heat content still contained in the exhaust gases of pellets. This additional yield of max. 15 % for pellets is at the same time the energy saving that is possible with condensing technology. Condensing technology also cleans the flue gas naturally. The emissions are thus significantly below the requirements of environmental labels such as the "Blue Angel". With a condensing boiler, not only can energy costs be reduced, but the environment can also be protected. The law supports this contribution with particularly attractive subsidy programmes.

The ideal conditions for operating a condensing boiler:

- Humidity-insensitive chimney (stainless steel or ceramic)

- Low-temperature heating system such as underfloor or wall heating. Heating systems with return temperatures > 40 °C (e.g. radiators) are technically possible, but not as efficient.

- Condensate drain into the duct connection

Unique concepts

System solutions with function guarantee

A heating system is only as good as the interaction between heat generators and consumers. At BRUNNER, all components of a log and pellet heating system are matched to each other in terms of control technology.

Comfortable

Everything fully automatic, low-maintenance and quiet - from ignition to ash removal. The ash container only needs to be emptied three to four times a year. All messages appear automatically on the display.

Variable

The output range adjusts to the current heat demand automatically

The infinitely variable, speed-controlled fuel metering system supplies the heating system with 4 to 17 kW.

Innovative

The integrated differential pressure measurement takes into account natural fluctuations in the negative pressure in the chimney and in the combustion air line (weather influences, seasons). Only the amount of air required for the required output is supplied. Fluctuations in fuel quality and quantity are detected during combustion by the integrated lambda sensor. In this combination, emission values significantly below the legal threshold values are achieved. Additional separation and filter devices are not required. The guarantee for a positive result in the recurring measurement by the chimney sweep.

Everything in view

Simple and intuitive operation

With the touch display, you always have your heating in view. All functions are displayed and operated centrally. In the online access to "my heating", the familiar display view is reproduced 1:1. Simply register with myBRUNNER and install the app. Access to your own heating is possible with any internet-capable end device.

A heating system that anyone can operate.

BRUNNER boilers have an integrated touch display. A quick glance is enough and the current heat situation of the building is recorded. All functions of the heating system - and not just those of the boiler - can be set and operated via the graphic interface. A second display with a white or black glass plate can be installed in the living room or entrance area. This way, you always have a quick overview of the current heating situation.

There is always room for pellets

4 m² floor space is sufficient - with or without cellar

This statement is not only made by customers who used to heat with oil. As a rule, the space where the oil tank used to be is sufficient here to store the year's requirement of pellets in a prefabricated silo. Not as sacks, of course. The pellets are blown dust-free from the tanker into a fabric silo or store room. From there, the quantity required by the boiler is "sucked in" fully automatically as needed. Either via a suction probe or diverter from below or a so-called pallet mole. This works extremely efficiently and diligently, as you can see in the video. Even in new buildings or in buildings without a cellar, space can be found for the year's supply of pellets thanks to flexible storage solutions.

No PLACE for a silo?

Choose the smallest "pellet store": the weekly container for manual filling. The ideal alternative if the storage container only needs to be filled every one or two weeks - such as in a new building. Pellets are offered in bags of 15 kg each and are easy to store. When full, the BRUNNER weekly container holds 300 kg of the wood pellets, which are automatically removed from below by a suction probe.

Compact and expandable

- The entire heating system requires no more than 1m² of floor space

- Stable construction enables transport with stair cllimber and sack trucks

- Expandable with 200-litre hot water tank

- Storage container for manual filling for a quick switch to pellets or as an alternative to the annual silo

- Due to the low-emission combustion, BRUNNER pellet boilers do not require a particle separator or fine dust filter.

- Our pellet boiler is well below the limit values of BImSchV, stage 2 - and with the best efficiency.

- The patented two-stage high-temperature vortex combustion chamber in the BRUNNER pellet boiler ensures the greatest possible heat transfer.

- The automatic heat exchanger cleaning contributes to a constantly high boiler efficiency.

- The better combustion of BRUNNER pellet boilers ensures less ash and longer emptying intervals.

- The spacious ash box is integrated into our pellet heating system to save space.

- The externally mobile ash box can be conveniently transported like a travel trolley.

- The casing of BRUNNER pellet boilers can be removed without tools.

- Exact graphic display of the fuel supply in the daily container as well as in the pellet stove.

- All operating states can be permanently queried and archived.

- Regular display of the ash volume - up to the request to empty the ash box.

- Control anywhere and at any time online with PC, tablet or smartphone using the myBRUNNER App.

- BRUNNER pellet boilers have whisper-quiet operation, low standby losses and minimal own power requirements.

- The eight-chamber rotary feeder with separate drive motor contributes to 100% burn-back safety in our pellet heating system.

- The separately driven metering and charging screws in BRUNNER pellet boilers provide additional fuel supply.

- Generously dimensioned and dust-protected drives make BRUNNER pellet boilers particularly safe to operate.

- BRUNNER pellet boilers are made of high-quality and environment-friendly materials - for a long service life.

- We give a five-year guarantee on our pellet boilers when a maintenance contract is concluded; this also applies to wear parts.

The design of the BRUNNER pellet boiler user interface enables all operating steps to be carried out intuitively by a short touch.

- Up to three touch displays can be connected.

- Determination and balancing of heat yields including standard performance measurement.

- Automatic archiving of heat yields, sensor values, information and fault messages.

- PIN code protected service level with various analysis functions for the service technician.

Make an appointment for a free consultation and let us work together to determine the ideal heating device for your home. We look forward to your visit.

Also use our social media channels to find out more.

.